Executive Director Chris Clowes provides his thoughts on what businesses should be considering when choosing a new 3PL provider:

Can you start by explaining how 3PLs have increased in popularity in recent years?

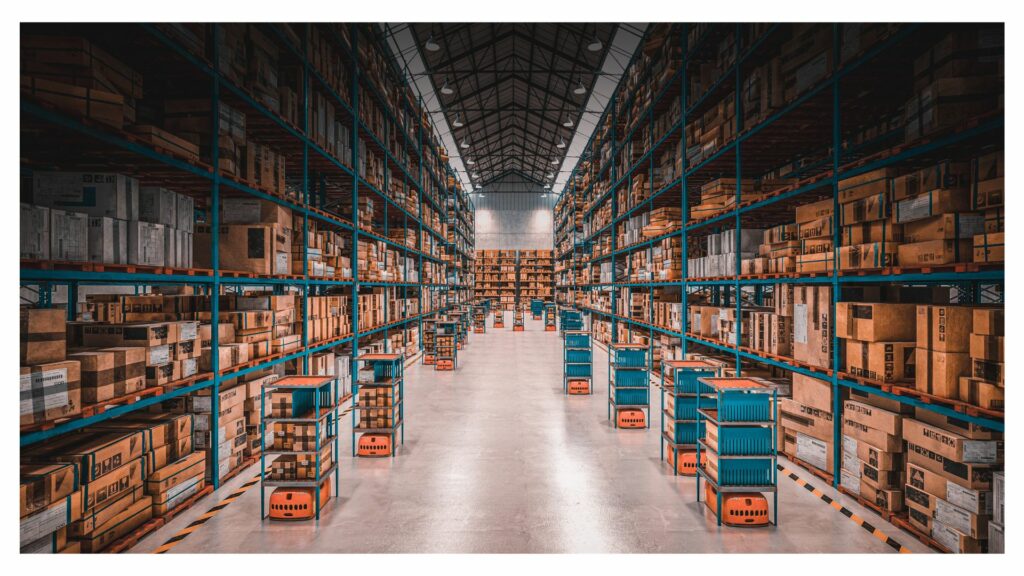

With the growth of e-commerce has come the rise of third-party logistics (3PLs). Manufacturers have increasingly needed to outsource logistics and supply chain management services to cope with fluctuating demand. Implemented effectively into wider operations, 3PL providers can increase the efficiency of supply chains by managing inventory, reducing costs, and offering increased visibility of operations.”

What are some of the common issues manufacturers experience with 3PLs?

“Unfortunately, partnerships don’t always drive the anticipated results. Poor communication, inconsistent service levels, lack of transparency and technology integration challenges are common concerns between manufacturers and 3PLs. Recently, for example, one major retailer was forced to apologise to some shoppers who experienced delays to their online orders as it moved to a new distribution centre. While some disruption may occur when changes are made to the logistics operation, businesses should take a strategic approach to selecting a provider, measuring the risks and ensuring they know what to expect in the months that follow.”

So, what considerations should manufacturers make when selecting a logistics provider?

1. Service capabilities

“The first consideration should of course be the 3PL’s service capabilities. Services will vary in complexity, specialisation and value-added features. For example, most offer basic logistics services including transportation, warehousing and distribution. While others have advanced services including integrated solutions that combine the three core functions and some have a global reach, providing international shipping handling, customs clearance and global logistics coordination. For smaller manufacturers, advanced logistics won’t be required, however as the business grows, its complexities will increase along with its logistics needs.

2. Flexibility potential

“Flexibility is also key to consider when selecting a 3PL provider due to the demand fluctuations that manufacturers have experienced in recent years. There is a consensus amongst manufacturers that global instability is here to stay. Therefore, 3PL services should allow for this through a flexible service. A flexible 3PL provider can scale operations up or down to quickly match demand variations. Additionally, companies may decide to enter new markets. With a flexible 3PL provider, the manufacturers can have their logistics strategies adjusted quickly to support new regions or products.

3. Cost structure

“Cost is arguably the biggest influencer when adopting a new service and working with a 3PL can help to make cost savings. Working with a cost-effective 3PL provider allows businesses to better predict and manage their logistics budget. Choosing a provider that is transparent and reasonable with pricing helps manufacturers avoid unexpected costs, which can strain a company’s financial resources.

4. Sustainability practices

“Sustainability credentials are also a growing concern for businesses, especially when selecting a service partner. Manufacturers are under pressure to prove their sustainability credentials to the government, customers and other key stakeholders; therefore, they should only work with partners that share the same sustainability ambitions.

5. Quality of customer communications

“It’s important to choose a provider that communicates well and responds to queries promptly. In logistics, issues such as shipping delays, inventory issues, and customs problems are common, therefore a responsive customer service function is crucial. The end customer’s experience is also heavily influenced by the efficiency of the logistics process. A 3PL provider that communicates well can enhance customer satisfaction by ensuring timely deliveries, handling returns smoothly, and providing clear information about order status.”

What steps should manufacturers take to ensure a strong partnership with a 3PL provider?

“This starts at the contract stage. A typical agreement should include a statement of work, objectives, payment terms, and relevant termination clauses. Once these items are established, the relationship has a strong foundation to cope with challenges.

“But beyond that, it should be a relationship of trust. Manufacturers are outsourcing their logistics operations, and they should trust the provider to do this without too much input or interference. However, regular reviews are good practice, perhaps bi-weekly to discuss day-to-day operational concerns and any small changes. Annually strategic planning meetings should be diarised too to discuss long-term strategies, evaluate the overall partnership, and review the past year’s performance. Without these annual reviews, it is easy to lose focus of long-term strategy and allow issues to fall under the radar.”

If you would like to know more about how SCALA can help your business with the transition to a new 3PL, please Contact Us for an informal discussion.